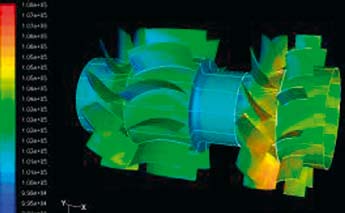

Since 2006 JSC “TEMZ” has been set itself up in the world market not only as the enterprise producing a wide spectrum of mining equipment, but also as a modern production of the European level with a high order of intelligence and technologies, capable to satisfy any wishes of the customer, creating intellectual systems of ventilation and automation with the required parameters «made to order». Application of the world leaders’ best achievements on the software development allows designers to model mathematically the air stream movement of a newly designed fan, optimizing the most complicated geometrical blade faces of runners and directing vanes, that allows to produce the machine with the best aerodynamic characteristics for a short period of time without manufacturing pre-production models.

Fig. 1. The mathematical analysis of the fan design

New generation of axial fans

The problem of noise of axial fans operating has arisen with the appearance of these machines irrespective of the place where they were used, on working tables or deep under the ground. The level of noise, emitted by fans, is one of the major operational characteristics of these machines. For a few decades JSC “TEMZ” has been producing mine fans of various versions and dimensions for needs of mining industry, including small fans with the diameter from 400 mm and large and heavy fans, with the diameter of runners more than 1200 mm, with high rates of exerted pressure, from 1700 Pa to 8000 Pa and over. Application of modern means of computer facilities and software ("FLUENT", "ProEngineer") using the techniques developed by FGUP "CAHI" (the Central Aerohydrodynamical Institute named for professor N.E. Zhukovsky) for the geometry analysis of blade faces of fans’ runners, carrying out of repeated experiments on optimization of the produced fans’ parameters allowed to create an extensive database.

New construction designs are being created on the basis of this base; they are equal to the world leaders’ production and on some parameters surpassing it. Today JSC “TEMZ” has the honour to offer essentially new fans to the market. Due to the last developments, including designs of fans with the integrated system of noise suppression, it was possible satisfying the GOST noise requirements not only to keep, but also to increase operational characteristics of fans in comparison with earlier existing models.

So on the basic frequency of 250 Hz

Fig. 2. Designing with the use of solid models

Fig. 3. Advanced fan VМE2.10

Automated fan control system

Automation of ventilation systems using frequency inverters provides power consumption reduction, and accordingly expenses for the equipment operation, prolongs service life of electric installations due to the modes of smooth start, braking and dynamic adaptation of capacities for the solving of the tasks with the changing load. The electric equipment life cycle increases due to the prevention of near miss incidents and emergencies.

Thus, reception of the prompt information on one of the constituent units failure allows to prevent destruction of the whole machine and, probably, to rescue people’s lives. The opportunity of the remote control of ventilation system (even through satellite control) allows to arrange the control unit in any convenient place to offer an opportunity for senior officials to supervise the ventilation system operation in real-time mode, to receive messages about near miss incidents and emergency situation. Control system monitoring of calendar routine maintenance with a mark about their execution allows to eliminate an opportunity of premature failure of the equipment, to facilitate the operational personnel’s work. The use of the automated control systems providing "soft" operating modes, excludes shock loads at start-up, eliminates changes of mains voltage, considerably prolongs service life of the fan, allows to adjust air stream parameters effectively, saving up to 25 % of the consumed electric power.

"Intelligent" motors

JSC “TEMZ” for assurance of fans design reliability as a whole, as well as for assurance of reliability of used electric motors at frequency regulation of rotation speed and specific use of motors inside the fan structure started development and manufacturing of all nomenclature lines of explosion-proof versions of electric motors used in its production. Motors for fans are developed on the basis of the general mathematical model of a fan drive. It is supposed to use in them advanced isolation materials, cable, impregnation technologies, bearings installation and application of greasings produced by world leaders, that essentially prolongs the engine service life. Most frequent reason of fans breakage is the failure of bearing unit of the motor on the outlet end of a shaft. This part of the engine will undergo the essential change in designs of motors for mine fans allowing to avoid overrun of the fan’s runner almost completely, to compensate its residual unbalance and its influence on the fans’ vibration characteristics as a whole. Despite of application of the frequency converter in the fan operation, all engines have an option of direct hard line start. The question of energy saving, mass and dimensions parameters and increase of engine efficiency is subject to detailed consideration. The heating mode of the fan’s motor windings standing ready for use is stipulated for isolation drying.